Your cart is currently empty!

3D printing

Turn your designs into physical models with 3D Printing.

Identify issues early and iterate more efficiently, saving time and money before full-scale production.

MadeByMichiel can model and facilitate 3D printed objects.

Tired of Expensive Design Mistakes?

Skipping the prototype stage can lead to expensive surprises.

Decisions are being held off because there is no tangible object to show stakeholders what the final result will be.

Or there is a need to iterate fast. Producing new end products is costly and the process takes a lot of time.

Without a model to hold in your hands, it’s easy to miss critical design flaws.

Cost-Effective Prototyping with 3D Printing

Instead of going straight to the end product, use 3D prints as intermediate step to check what your product is going to look and feel like.

This way, you can fix problems early and avoid costly errors down the line.

The Process:

- We start by discussing the prototype’s purpose and reviewing your design for printing in 3D.

- We 3D print the model, ensuring it matches your design needs.

- You get a solid prototype that helps you refine your design and move forward with confidence.

Case studies:

Have a look through various case studies.

-

Collectible Character Toys

How the case study started A small story about the steps involved with starting the project. Why? What problem was there that the project set out to solve? Show the case study in development Part one of the case study being developed SHow further development Some synopsis at the end. Gallery Here are more images…

-

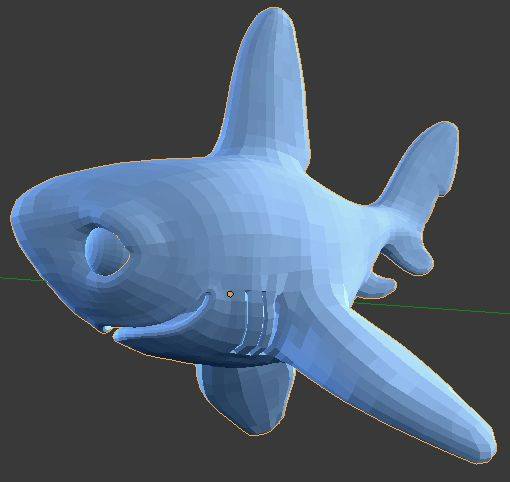

Sammie the Shark

A 3D printed cartoon shark key fob for tourists.

-

Stickman Eggcup holder

How the case study started A small story about the steps involved with starting the project. Why? What problem was there that the project set out to solve? Show the case study in development Part one of the case study being developed SHow further development Some synopsis at the end. Gallery Here are more images…